Story and photos by Mark Wing

Joining us for the first time at a Larry’s Garage Work Day was Dr. Bruce Onofrey. Bruce has taken more an interest in automotive mechanics and electronics since his recent retirement as a professor of Optometry in Houston, TX. Although Bruce collects German sports cars, he was curious to see Larry’s workshop and the work in progress there. Club members working on projects this day included Phil Lance, Kirk Peterson, and Mark Wing.

Phil Lance was putting new linings on a set of 1926/27 brake shoes for his speedster project.

Kirk Peterson was installing a Texas T-Parts style high-volume oil line for his 1925 coupe “Buster”. Buster is destined to compete in the Montana 500 race this year and he and Larry have been hard at work preparing a 1926/27 engine for the race.

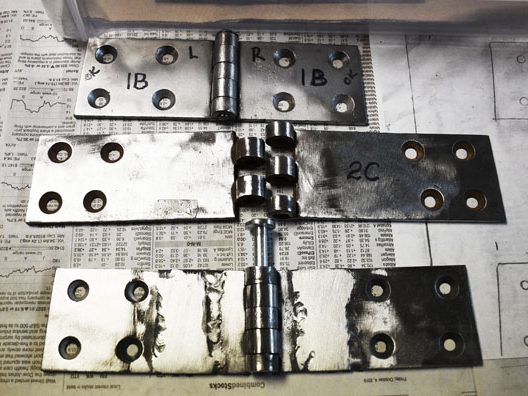

Mark Wing continued media blasting parts for his 1915 Coupelet project. The metal body parts for this restoration project are being restored and shipped to Ray Wells in El Cajon, CA. Ray is well-known and highly respected in the Model T hobby as the “go to” person if you need a body built. He’s restored or recreated several 1915 and 1916 Coupelet bodies. In the case of this 1915 Coupelet body – several batches of parts have been restored and shipped to Ray depending on the priority in the rebuilding process. At a previous Work Day, door hinges (3 per side) were being media blasted, hinge pins created, and metal fillers cut and welded when the hinges were too short. Cast metal parts, such as the top hinges and Landau bars, were very rusty and had to be loosened up to move freely again prior to final cleaning and painting. The sheet metal (that survived the late 1980’s garage fire) has been more challenging. These panels typically require welding/brazing and leading. No plastic body fillers were used before shipping to Ray as he will have to “muscle” these panels in place to mate with the wood body he’s building. Plastic fillers could crack or break if flexed too much. Lead is very pliable and can be worked with a hammer and dolly later if necessary. Final body panel refinement will be done once the body is fully assembled and prior to painting.

Thank you Larry for a great Work Day at your garage!